Inspection and Test Plans (ITPs) in Construction: What They Are, Why They Matter, and How to Create One

Quality control on a job site rarely feels simple. Some days, everything lines up. Other days, the team is juggling drawings, approvals, and inspections while trying to keep work moving. Most general contractors I’ve worked with have seen how small issues start to stack up when the checks are not organized.

Inspection and Test Plans (ITPs) exist to keep those leaks from spreading. They take the scattered parts of quality control and put them into one routine. Instead of relying on memory, quick conversations, or an inspector’s availability, an ITP sets out what needs attention and when.

It is a straightforward tool. Still, I find it crucial to explain the core concepts of a construction ITP to help you maintain a level of consistency that is otherwise hard to achieve.

Table of Contents

- What Is an Inspection and Test Plan (ITP)?

- Core Elements of a Strong ITP in Construction

- Step-by-Step: How to Create an Inspection and Test Plan

- How Digital Construction Tools Improve ITP Management

What Is an Inspection and Test Plan (ITP)?

An Inspection and Test Plan is a working document used to outline how inspection and testing will happen across a project.

It lists each activity, the checks required, the standards that apply, and the evidence needed to confirm that the work meets those expectations. Most teams treat it as the guide they refer to when moving from one stage of construction to the next.

In practice, an ITP serves as a roadmap for keeping every task aligned with the project’s specifications and the legal or technical requirements tied to it. It includes contract documents, industry standards, and any local rules that apply. When crews follow the plan, the process becomes predictable. Everyone knows what will be reviewed and what must be approved before work continues. An ITP also helps avoid disputes, because the expectations were clearly defined from the start.

ITPs Within the Broader Quality Management System

While an ITP sits on its own as a document, it is actually part of a larger quality framework. Most builders have company-level policies that come from a Quality Management System (QMS). These policies often follow ISO 9001 or internal QA guidelines. The ITP is where those high-level ideas turn into daily routines.

A QMS identifies what the organization values, such as traceability, compliance, or risk reduction. The ITP translates those concepts into practical steps. When a risk assessment shows certain tasks carry more impact, the plan will include more detailed procedures and Hold Points. Simpler or low-risk activities may only need a basic check. Such a balance keeps the process realistic while still providing control.

Core Elements of a Strong ITP in Construction

A reliable Inspection and Test Plan works only when its structure is clear, and its expectations are unambiguous. Builders use ITPs to establish exactly what will be inspected, when the inspection will occur, and who is responsible for verifying compliance at each stage.

The goal is simple: to prevent avoidable rework and document every quality-critical step with the right level of oversight.

An effective plan typically includes several foundational components. Each of these elements reduces risk in a different way and provides the traceability that clients, inspectors, and builders expect on complex projects.

Hold Points vs. Witness Points vs. Review Points

Projects use several types of inspection points, and each serves a different purpose. I’ve seen many teams often mixing them without thinking about why they are there, so it helps to keep a clear distinction.

A Hold Point is the strictest.

Work stops until the responsible party signs off. For example, before pouring concrete, the reinforcement layout might be a Hold Point. If the steel is not inspected at that moment, you lose the chance to verify it later. These points protect critical stages where mistakes would be costly or impossible to correct.

A Witness Point is more flexible.

The inspector or client representative is invited to attend, but the work cannot continue if they do not show up.

Typical use: testing soil compaction, pressure testing pipes, or checking frame alignment. The team documents it, and the inspector reviews the results afterwards.

A Review Point is the lightest touch.

It often involves checking documents, such as a test report or a material certificate. It’s used when the work itself is straightforward but still requires confirmation for compliance.

Choosing between them depends on the risk level:

- High-risk tasks get Hold Points.

- Medium-risk steps often get Witness Points.

- Administrative or lower-risk reviews stay as Review Points.

Acceptance Criteria

Acceptance criteria define what “good” looks like. Without them, inspections turn into subjective conversations rather than clear evaluations. A project may use several types of criteria, and each comes from a different source.

Some criteria come directly from standards, like required compressive strength for concrete or specific tolerances for steel sections. Others are part of the project documents, such as installation methods described in specifications.

Manufacturer guidelines also matter, especially when dealing with specialized materials or equipment.

Examples:

- Strength requirements for concrete cylinders

- Maximum variation allowed in slab levelness

- Installation clearances for mechanical equipment

The goal is clarity. If the inspector and the crew understand the benchmark, decisions are made more quickly and disputes are rare.

Regulatory Compliance

Every project operates under a framework of codes, standards, and safety regulations. ITPs serve as the bridge between those high-level obligations and the daily inspection work performed on site.

By embedding code references, mandatory inspection stages, and required certifications directly into the plan, builders ensure each activity is executed and verified in line with legal expectations. It reduces compliance-related risks and supports smoother approvals from building authorities.

Roles and Responsibilities

An ITP in construction only works if everyone knows their role. On many sites, these responsibilities overlap, so it helps to map them out clearly.

The QA/QC Manager oversees the entire inspection process. They make sure the ITP follows company policy and verify that records are complete. They are also the primary contact for auditors or client representatives.

The Site Engineer usually performs the inspections or coordinates them. They check the work, confirm that the criteria are met, and prepare documentation.

Contractors and subcontractors carry out the work and prepare it for inspection. They need to know the inspection sequence so they do not close or cover tasks prematurely.

Third-party inspectors might be required for certain tests, such as welding certifications or soil testing. Their reports often become mandatory documents in the ITP.

Client representatives may participate in Hold or Witness Points. Their involvement provides transparency and helps build trust during key stages.

Defining these roles early prevents delays, because everyone knows who needs to be present before work continues.

Documentation Requirements

Even the most thorough inspection does not mean much if it is not documented properly. Projects rely on several types of records, and each serves a different purpose.

- Checklists help the team remember the steps of an inspection.

- Test reports and lab certificates confirm that materials meet requirements.

- Photos are used more often now, especially when something will be covered up soon after installation.

- Site records, including daily logs, provide context that inspectors sometimes need.

Construction document management software makes this part easier. When photos, reports, and forms are stored in one system and tied to specific tasks, it reduces the chance of missing files. It also keeps everyone updated without searching through email threads or shared folders.

Step-by-Step: How to Create an Inspection and Test Plan

Creating an ITP is easier when you break the process into clear stages. Most teams I’ve worked with follow a similar sequence, even if the documents look different from project to project. What matters is that each step gives the crew enough clarity to move forward without confusion.

Step 1: Break Down Activities

Start by listing the work in the order it will happen. The project scope, takeoffs, and method statements help outline the major tasks. It doesn’t need to be perfect on the first pass. You simply want a structure that follows the progress of the job.

A typical list might look like this:

Earthworks, then foundations, then the framing package, after that, mechanical and electrical work, and eventually the finishes. Each of these large tasks contains smaller activities that will later appear in the ITP.

This breakdown helps you see which parts of the build carry more risk and where inspections must happen before work is covered.

Step 2: Identify Inspection and Test Requirements

Once the tasks are outlined, go through each one and ask what needs to be checked. Some inspections come directly from code requirements. Others are found in project specifications, design notes, or manufacturer guidelines.

Concrete placement, for example, requires several checks: reinforcement layout, form alignment, concrete mix verification, and curing conditions. Mechanical equipment installation may need alignment tests, power checks, and commissioning procedures.

💡Look at each activity through the lens of compliance. If something must meet a specific requirement, it belongs in the ITP.

Step 3: Define Acceptance Criteria

Now you are adding more precision to the plan. Each inspection item needs a benchmark. These benchmarks could be measurable values, visual conditions, or documentation-based confirmations.

For example:

- Slab levelness within the tolerance specified in the drawings

- Proper torque for bolted connections

- Pressure test results meeting the required range

These criteria make the inspection objective. Without them, you end up with opinions instead of decisions.

Step 4: Assign Responsibilities

The ITP should clearly show who performs each check. This helps avoid delays, especially when multiple parties are involved.

The Site Engineer might handle dimensional checks. The QA/QC Manager may review documents. A certified technician could be required for certain tests. The client representative may attend specific stages.

💡Spelling this out reduces last-minute calls asking who needs to be present before covering up the work.

Step 5: Add Hold, Witness, and Review Points

Every task carries a different level of risk.

Hold Points stop work until approval is given. Common examples are reinforcement checks, waterproofing inspections, and major installations that will not remain accessible later.

Witness Points allow work to proceed if the inspector does not attend. Soil compaction tests or framing alignment checks often fall into this category.

Review Points are usually for documents. Material certificates, lab results, and inspection summaries are typical examples.

Choosing the correct point helps keep the workflow steady while keeping the critical checks under control.

Step 6: Establish Documentation Requirements

Now the plan needs to show which documents belong to each stage. It could be a checklist, a test report, a lab certificate, or a set of photos.

Projects run better when the team follows consistent naming and filing habits. Documentation gets lost easily when everyone uses different systems. Digital tools help maintain order by tying records to activities. This makes it easier to pull information for client meetings or audits.

Step 7: Build the ITP Template or Table

Most ITPs use a structured table. The format can change depending on the company, but the core elements usually stay the same.

Typical columns include:

- Activity or task

- Reference standards

- Type of inspection

- Responsible party

- Inspection method

- Acceptance criteria

- Frequency

- Documentation required

- Sign-off

By placing this information in a single table, the team can follow the inspection sequence without flipping through multiple documents.

Step 8: Review and Approval

Before the ITP becomes active on-site, it needs a review. Engineers, QA/QC personnel, and client representatives check the document to confirm that the steps align with the contract and regulatory requirements.

During this review, common errors may appear. Missing standards, unclear responsibilities, or vague acceptance criteria can slow the approval process. It helps to walk through the plan as if you were the inspector. If anything feels unclear, it probably needs refinement.

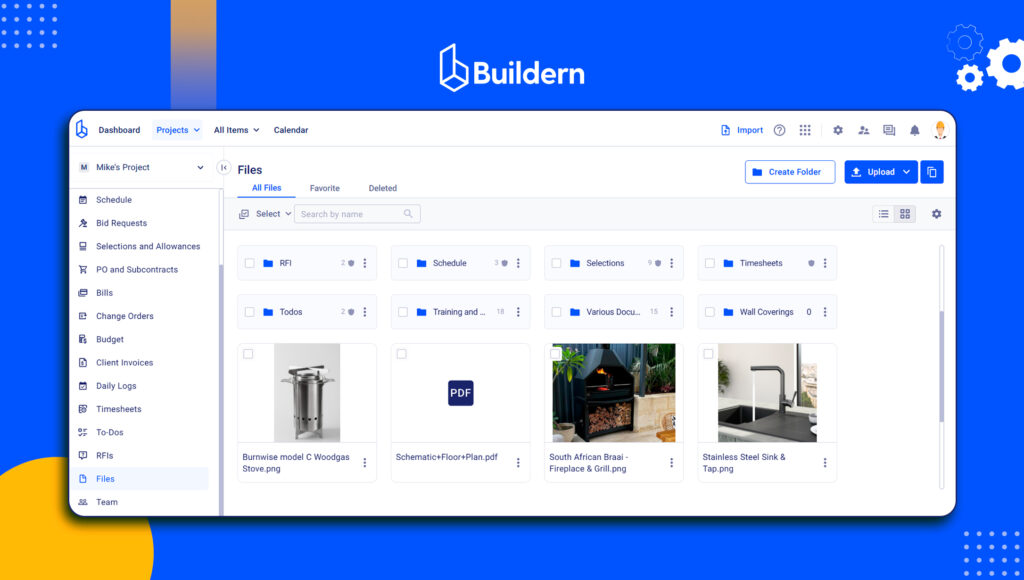

How Digital Construction Tools Improve ITP Management

Digital systems have changed the way teams handle inspections. Paper forms and scattered folders often slow things down, especially when work needs to be verified quickly. A well-structured digital workflow keeps information in one place and reduces the time spent searching for records or waiting for updates from the field.

Automated Record-Keeping

A digital platform captures inspection details as soon as they are submitted. This cuts down the number of missing documents and helps the team verify what has already been reviewed. It also makes it easier to compare the actual progress with the planned inspection sequence.

Checklists Tied to Tasks

Instead of checking separate files or printed forms, inspectors can open the specific task and see the checklist attached to it. This keeps the inspection consistent, even when different team members handle similar activities.

Cloud-Based Storage for Photos and Reports

Photos, test results, and certificates often get lost when shared through email or messaging apps. Storing them in a central system gives the team access to the information without requesting it again. This becomes especially useful when the work is covered soon after installation.

Real-Time Communication Between the Site and Office

When inspections rely on immediate decisions, quick communication matters. A shared digital workspace lets field teams update the office and receive feedback without long delays. This helps avoid situations where work continues without the required approval.

Version Control

ITPs often change as the project evolves. Digital version control prevents old forms from circulating on-site. The team sees only the latest approved document, which lowers the risk of outdated instructions being used on active work.

Faster Client Approvals

When client representatives can review documentation remotely, approvals move quickly. Instead of waiting for in-person visits, the documents and photos can be reviewed as soon as they are uploaded. This keeps the workflow steady and reduces idle time between stages.

Final Thoughts

When I put together an Inspection and Test Plan, I think of it as a simple way to keep the job predictable. It helps the teams stay ahead of the checks that matter, keep everyone aligned, and avoid the kind of surprises that slow a project down. A clear ITP won’t solve every problem on a site, but it creates enough structure to let the team work with confidence.

With the right sequence, defined criteria, and clean documentation, the day-to-day decisions feel less chaotic. And once the plan is supported by a digital workflow, it becomes much easier to track progress and keep records organized.

In my experience, that combination is what keeps quality control steady from the first activity to the final handover.